Many companies today own and rely upon automated equipment that improves efficiency and cuts costs. Making appropriate arrangements of various kinds can add even more to the value of such assets.

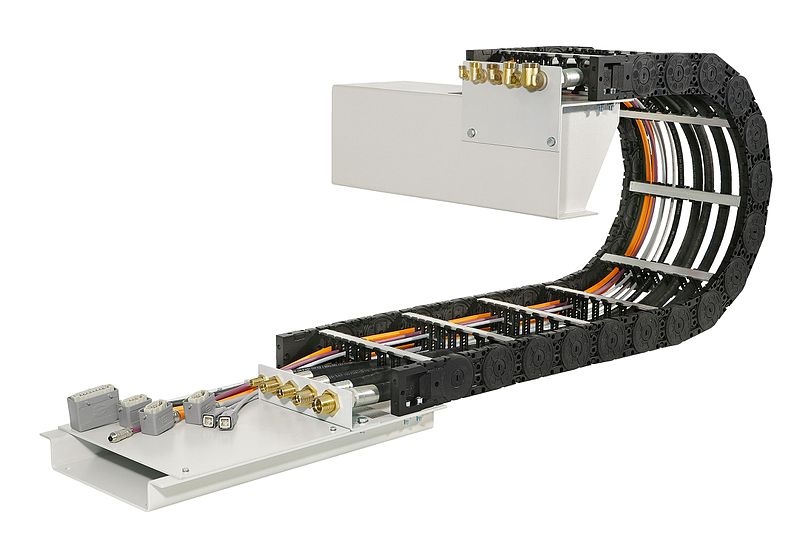

Flexible, high-quality cable, hose, and line carriers provide protection that keeps automated machines running more reliably. A modest investment into customized carrier assemblies can produce truly impressive returns.

Protecting Delicate Lines and Hoses in the Most Difficult and Demanding Environments

Cable and hose carriers like those listed at Dynatect.com can prevent a wide range of problems common to automated equipment. Many such machines include supporting features like hydraulic hoses, electrical cables, and supply lines that are not meant to withstand much stress. The failure of a single line or cable, though, could take a machine costing $150,000 or more out of service, with losses mounting all the while.

As the movements of a machine will often make rigid types of protection impractical, cable and hose carriers are designed and constructed so as to enable plenty of flexibility. With each of the individual links of a finished cable carrier also being strong and resistant to impacts, cables and hoses remain both well organized and protected from environmental hazards.

Properly Customized Cable Carriers Await

What matters the most when choosing cable and hose carriers for particular applications is having access to products that are customized to suit the relevant requirements. A cable carrier must be well suited not only to the machine it will be attached to but also to its surroundings.

That will require settling on a number of important details so as to ensure a close fit. Some of the issues that will need to be addressed in most cases include:

- Material. Cable and hose carriers can be made from metal, rugged plastics, or a combination of materials. Metal carriers tend to hold up better to high temperatures than those made of plastic, but are normally heavier, as well. With automated machines that run at particularly high speeds, the light weight typical of plastic carriers will often be an advantage. Even though plastic carriers normally weigh less than metal ones, the latter tend to feature more favorable strength-to-weight ratios.

- Link type. Carrier links with open faces make it easier to keep up with the inspection and maintenance of cables and hoses contained within. Closed-link carriers will normally provide more protection, both from direct threats like impacts and indirect ones like heat. The choice of link style will also sometimes influence the ability of a given carrier to keep lines well organized under certain operating conditions.

- Travel. The length of a customized carrier should be set so as to allow the full range of motion for a machine and little more. An overly long carrier can become unnecessarily difficult to manage and could even cause other related problems to arise. A carrier that does not provide enough travel will impede the performance of a machine.

An Investment That Quite Often Makes Sense

Customized cable and hose carriers will normally cost a small fraction of the amounts spent on the machines to which they are fitted. Given the protective, organizational, and other benefits that come from installing high-quality carriers, most such investments will pay off. Choosing the most appropriate type of customized carrier for a given machine and facility will make significant returns even easier to achieve.

Featured Image