Some industries demand precision and intricately manufactured parts. When your manufacturing business requires such parts, CNC machining is the way to go and you can always consider buying from this dealer for your CNC machining needs. This method is quickly rising in popularity, with the global market expected to reach $129 billion in 2026.

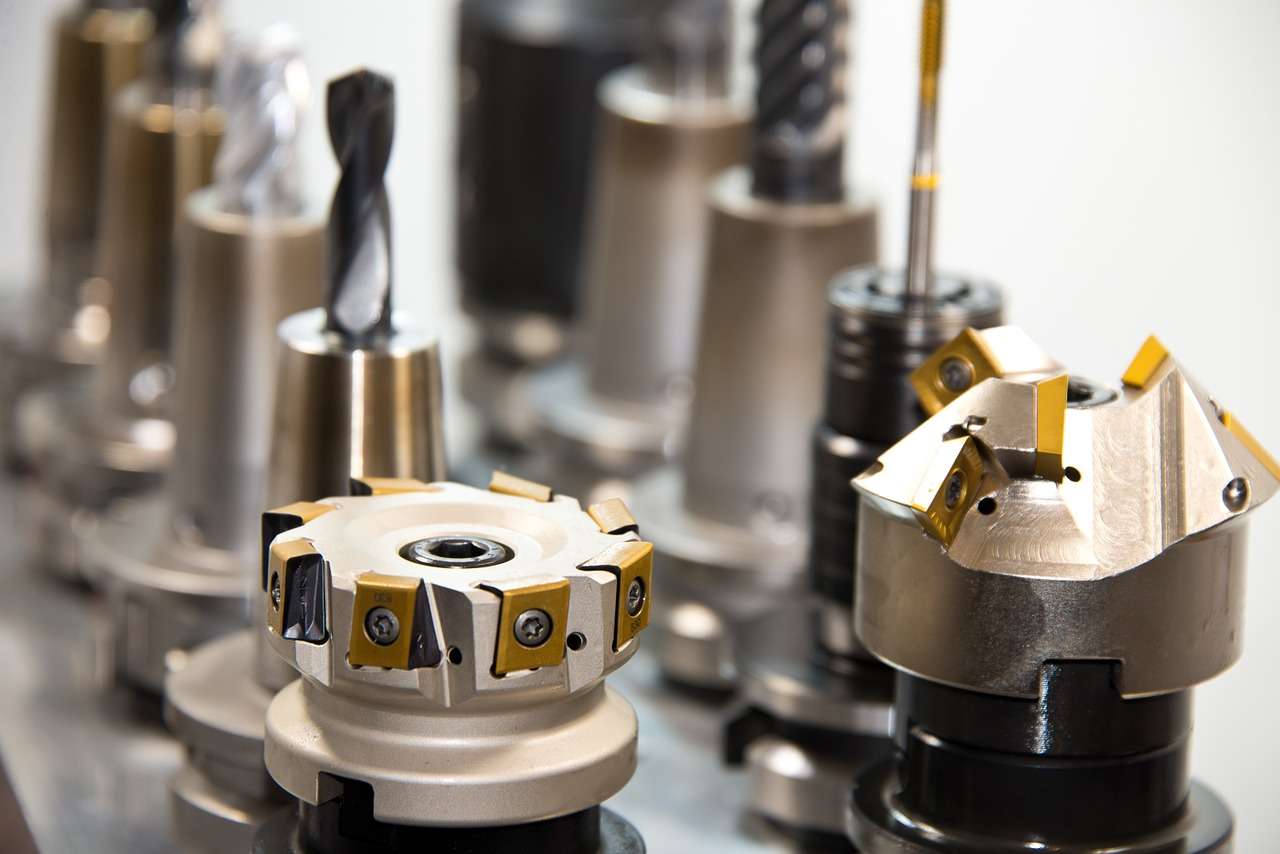

CNC machining is a popular prototype production method that employs automated tools through computer programming inputs. Multiple factors, such as the demand for reduced manufacturing errors, lower operating costs, using human resources efficiently, and adapting to growing IoT technologies and predictive analysis contribute to its growing success.

While CNC machining is influenced by the growth of automation across production processes and awareness regarding industry 4.0, it’s also reflective of the evolution of industries that use CNC machining. Industries such as the medical and aerospace ones are heavily dependent on CNC machining due to their demand for accuracy, which can become a matter of life and death.

This is why many industries can benefit from this level of precision. It’s also excellent for industries that are constantly updating due to changing technologies. Rapid manufacturing can help a firm quickly create prototypes and test them.

Here are six industries that rely on CNC machining and benefit from it.

Medical Industry

The medical industry requires custom products that fit the needs of patients. Additionally, the industry also uses disposable tools to prevent cross-contamination. This is why tools need to be produced accurately and at a rapid pace to ensure all patients are catered to.

CNC machining is an excellent option to create parts that are suited to every patient. Even a slight error in a part such as optical lenses can prove detrimental, making it imperative to reduce the error rate as much as possible.

Since CNC machining essentially uses computer programming, it can reduce the risk of errors and maximize accuracy. The technology can also be used to manufacture prototypes for medical-grade silicone devices, for example, that could potentially save lives.

Aerospace Industry

Aerospace vehicles, such as fighter jets and airplanes, are regularly exposed to factors such as extreme pressures, high speeds, and fast air currents. To prevent an aircraft’s wear and tear, an engineer must carefully manufacture each part since even a slight deviation could result in a catastrophe.

CNC machining can meet this demand for precision due to its high tolerance level. Using this technology, machinists can create tolerances with plastics, titanium, aluminum, and nickel. It can develop precise components and devices, such as electrical connectors, antennae, manifolds, and airfoils, that can help meet the demands of the aerospace industry.

Experimentation is a critical part of the aerospace industry and, without testing different parts, it would not have been as advanced as it is today. CNC machining is an excellent option for this since it allows machinists to create accurate parts and make changes quickly.

Electronics Industry

While CNC machining is typically used to create large parts, it’s also a great option to make small components such as those used in electronics. The usage of CNC machining in this industry is growing with the demand for miniaturization in consumer electronics, increasing the dependence on smaller and powerful compact lightweight parts.

CNC machining can expertly handle the specialized components demanded by the electronics industry, managing even the tightest tolerances for small components even when the volume requirement is high. Typically, the smaller the part, the tighter the tolerance. Since there is minimal room for error in the micromachining process, CNC machining can help achieve accuracy levels that were previously impossible manually.

Apart from components such as insulators that need to be manufactured for electronics, the industry can also produce communication components through CNC machining. These parts can create an electrical connection between different elements, such as electrical insulation, amplifier housings, and heat sinks, making them vital for the electronics industry.

Oil and Gas Industry

The petrochemical industry demands well-machined parts that accurately fit together to create large machines used on drilling rigs and refineries. Errors such as valves that leak, cylinders that may not fill, and pistons that may not create pressure can cause many issues. To maximize productivity in a petrochemical facility, CNC machining can help create parts that improve efficiency.

For instance, drilling rigs require components with high tolerance levels since they’re located in isolated areas. This means that getting a replacement could take ages if a part is faulty, heavily impacting the production process. Parts created for use in drilling rigs must be resistant to regular wear and tear, such as those created from salt spray and dust, to ensure smooth operations.

The oil and gas industry operates rapidly, making quick turnarounds and high-volume processing a priority. CNC machining can help fulfill these demands by producing small or large components for the industry that match the precision it requires.

Automotive Industry

Similar to the aerospace industry, another industry that heavily relies on CNC machining is the automotive industry. CNC machining can create components such as engine parts, which are typically created after an intensive research and design process. This technology can help boost the prototype process by speeding up the testing phase and creating components that match exact specifications.

Typically, the aerospace industry demands speed while, on the other hand, the automotive industry requires components that are strong enough to last in the long run. CNC machining can create these parts for vehicles such as shipping vessels, passenger rails, passenger vehicles, transport trucks, and freight trains.

Since CNC machines are equipped with the ability to create components from different kinds of materials, it can create a variety of components used in engines, brakes, and other parts of an automotive vehicle. The industry’s demands are quickly changing, with an increasing requirement for efficiency. CNC can adapt to these trends by quickly creating prototypes that can be tested and changed if needed.

Defense Industry

Just as the oil and gas industry requires parts robust enough to withstand harsh environments, so does the defense industry. The military needs to follow strict government regulations and must ensure any parts created abide by these rules.

Since the military typically involves various sectors, its parts could bear similarities with those created for other industries, such as electronics, transportation, and aviation. However, what sets this industry’s demands apart is keeping up with new technologies that ensure parts remain operational in the most secluded areas.

While the industry’s nature demands secrecy, it can benefit from CNC machining by constantly updating parts and testing them. Since technology can create parts from strong materials, it can produce a high volume of parts with tight tolerances.

Final Thoughts

CNC machining can provide many benefits to a wide range of industries. It’s quickly becoming the go-to option due to its ability to produce customized parts. It can quickly adapt to changes and, that way, become an ideal choice for a continually changing world due to technological developments. For any firm that wants to speed up its processes, regardless of the industry it belongs in, it can greatly benefit from this groundbreaking technology.